Automatic Ball and Flat shape lollipop making machine

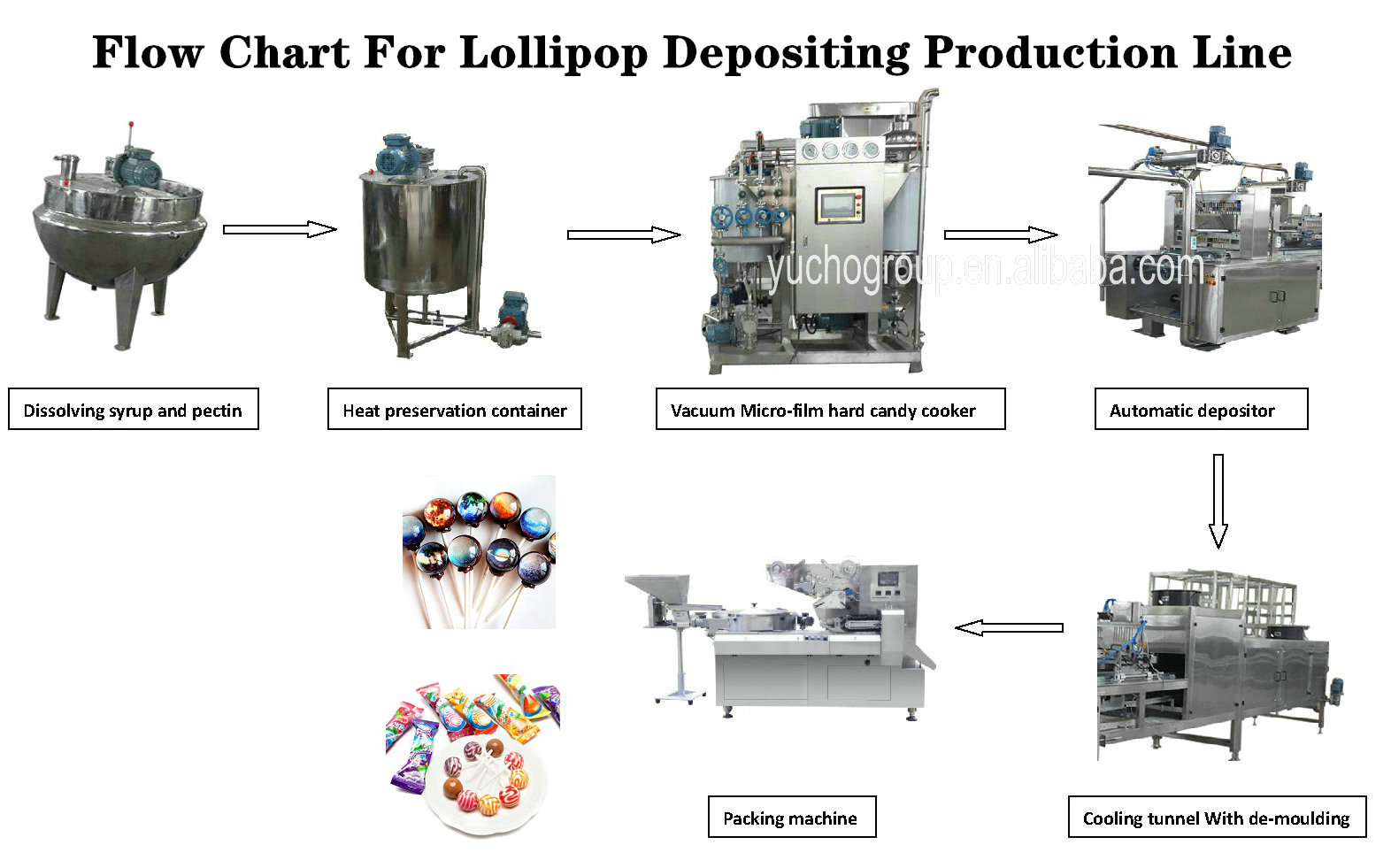

YCL150/300/450/ 600 Hard/lollipop Candy depositing line is advanced equipment which can continuously produce various kinds of hard candies under a strict sanitary condition. This line can automatically produce high-quality hard candy, such as single color candy, two-color candy, crystal candy, central-filling candy, etc. The processing line is also an advanced and continuous plant for making different sizes of ball-type lollipop candies, also can make the two-color striped lollipops, and ball-type lollipop (stick –adding can be done automatically). It also can make toffee candy, just to change the sugar cooking system.

| Model | YGL50-80 | YGL150 | YGL300 | YGL450 | YGL600 |

| Capacity | 15-80kg/hr | 150kg/hr | 300kg/hr | 450kg/hr | 600kg/hr |

| Candy Weight | as per the candy size | ||||

| Depositing Speed | 20-50n/min | 55 ~65n/min | 55 ~65n/min | 55 ~65n/min | 55 ~65n/min |

| Steam Requirement | 250kg/h, 0.5~0.8Mpa | 300kg/h, 0.5~0.8Mpa | 400kg/h, 0.5~0.8Mpa | 500kg/h, 0.5~0.8Mpa | |

| Compressed air requirement | 0.2m³/min,0.4~0.6Mpa | 0.2m³/min,0.4~0.6Mpa | 0.25m³/min,0.4~0.6Mpa | 0.3m³/min,0.4~0.6Mpa | |

| Working Condition | /Temperature:20~25℃;n/Humidity:55% | ||||

| Total power | 6kw | 18Kw/380V | 27Kw/380V | 34Kw/380V | 38Kw/380V |

| Total Length | 1meter | 14m | 14m | 14m | 14m |

| Gross Weight | 300kg | 3500kg | 4000kg | 4500kg | 5000kg |

lollipop depositing machine / lollipop making machine

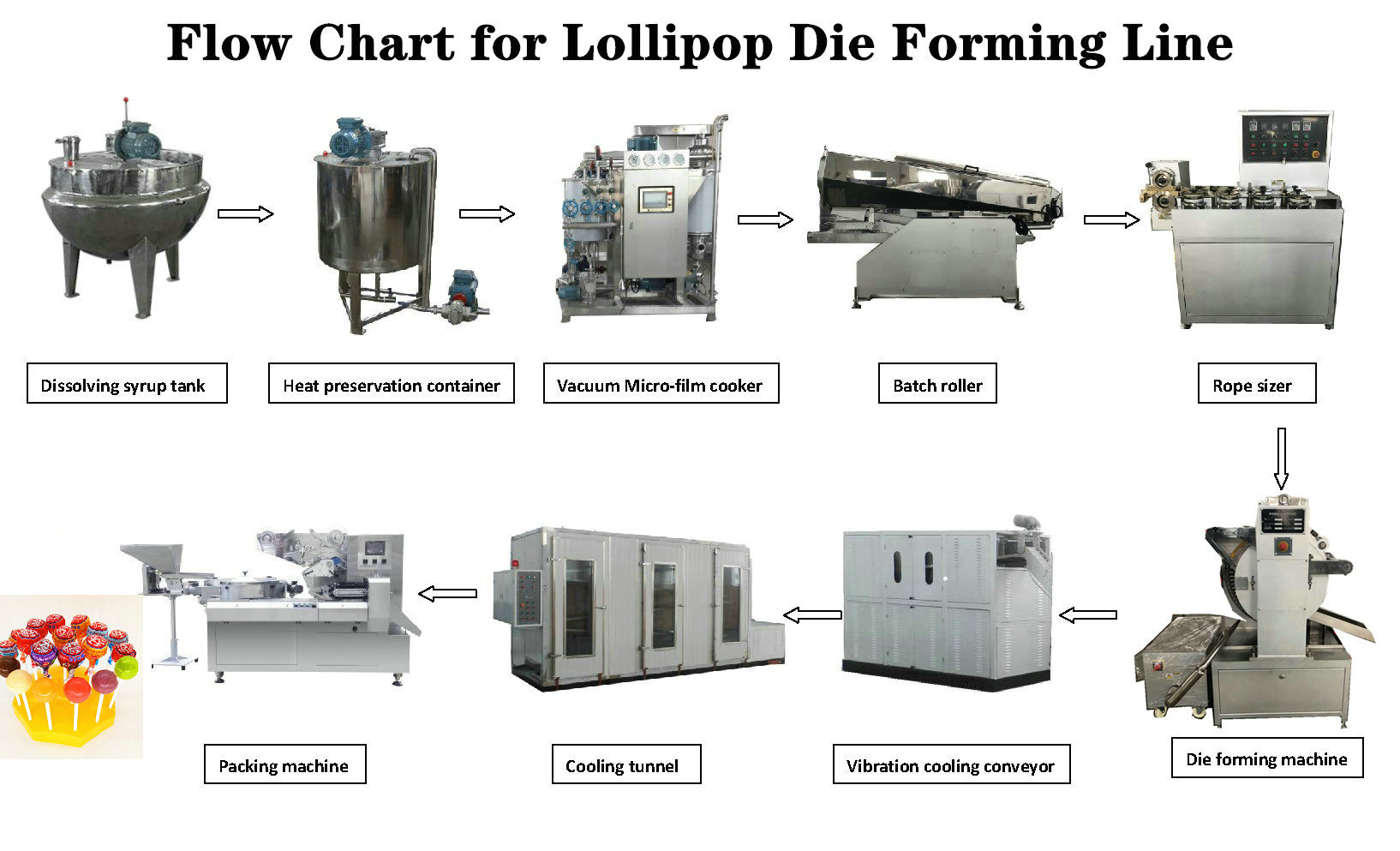

Lollipop die forming produciton line is a high-powered candy die-forming equipment. It is consists of the centre filliting machine, rope sizer, liner, former, cooling tunnel. These lollipop machine conbined by machine, electricity and air, can controlling centre filling, lining, former, structury tightly, designing resonable, with high automaticly, it is ideal candy forming equipment.

Lollipop forming machine is suitable for producing irregular-shaped lollipops, such as: oblate, oval, big foot and cartoon irregular-shaped lollipops (shapes varying according to customer requirements).

| Name | Dimension (L*W*H)mm | Voltage(v) | Power (kw) |

Weight (kg) |

Output | |

| YC-200 | YC-400 | |||||

| Batch roller | 3400×700×1400 | 380 | 2 | 500 | 2T~5T/8h | 5T~10T/8h |

| Rope sizer | 1010×645×1200 | 380 | 0.75 | 300 | ||

| Lollipop Forming machine | 1115×900×1080 | 380 | 1.1 | 480 | ||

| 1685×960×1420 | 380 | 3 | 1300 | |||

| Cooling sifter | 3500×500×400 | 380 | 0.75 | 160 | ||