Jelly Gummy Candy Making Machine

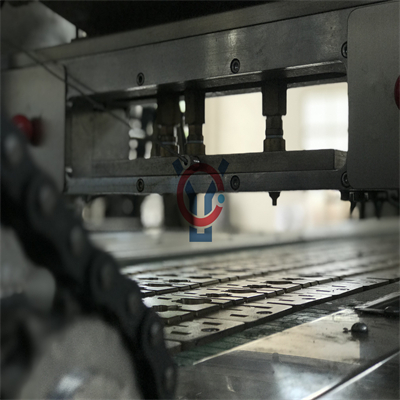

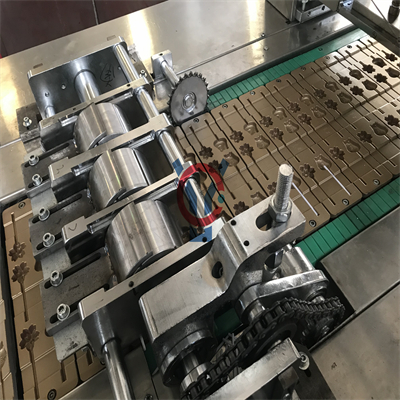

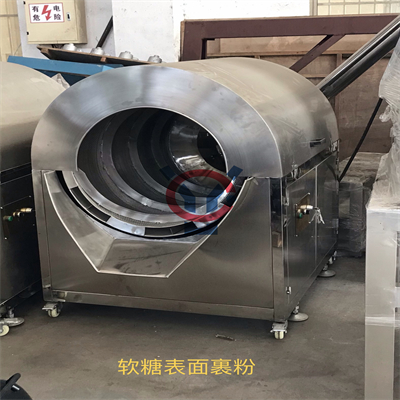

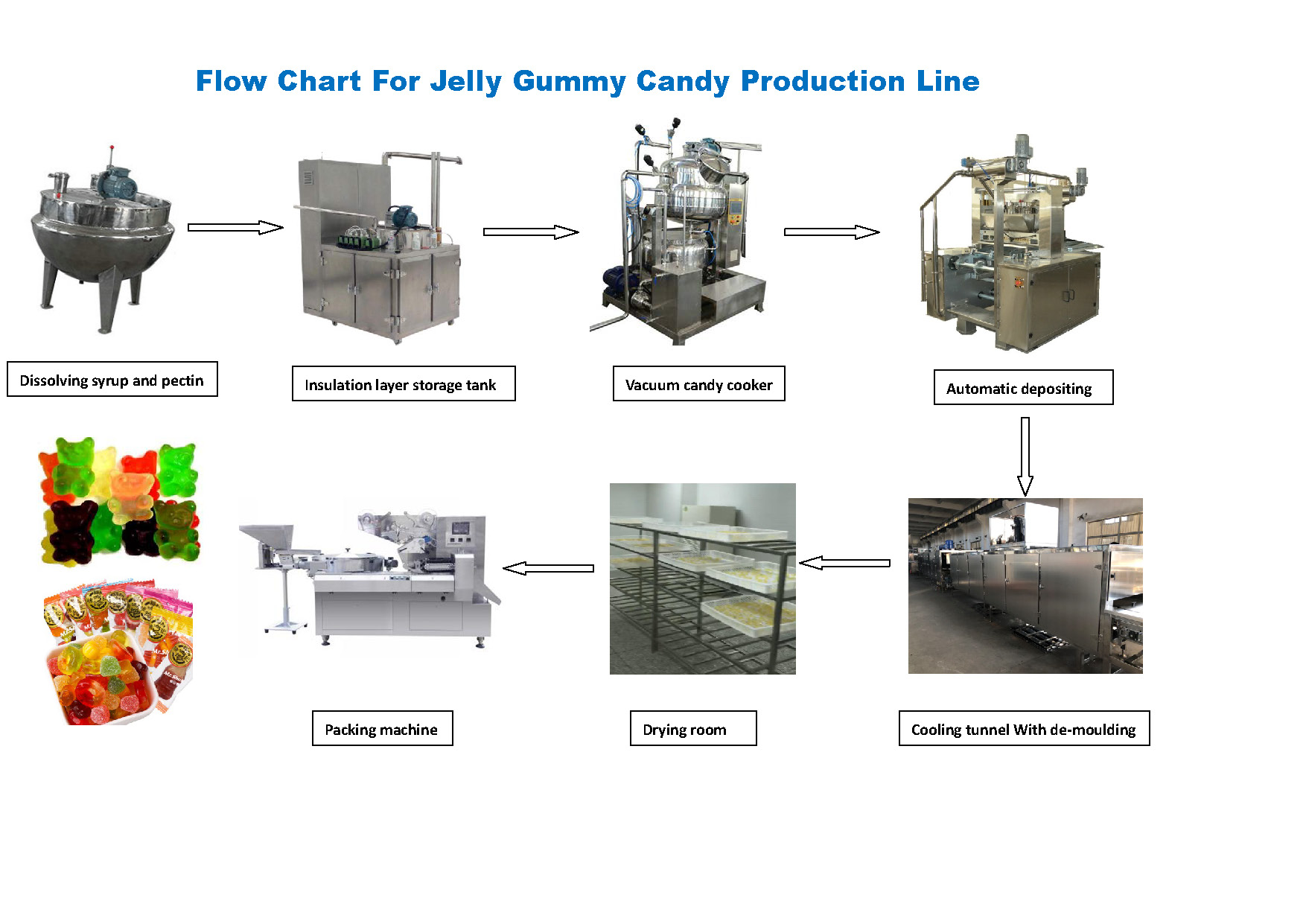

Gummy(Jelly) candy processing line is an advanced and continuous plant for making different sizes of jelly candies (QQ candies) it is an ideal equipment which can produce out good quality products with the saving of both the manpower and the space occupied. This gummy candy depositing line consists of jacket dissolving cooker, gear pump, storage tank, storage, discharging pump, storage tank, discharging pump, color&flavor mixer, depositor, cooling tunnel, cooling tunnel, electric control cabinet,etc.

Technical Specifications

| Model | YGDQ50-80 | YGDQ150 | YGDQ300 | YGDQ450 | YGDQ600 |

| Capacity | 15-80kg/hr | 150kg/hr | 300kg/hr | 450kg/hr | 600kg/hr |

| Candy Weight | as per the candy size | ||||

| Depositing Speed | 20-50n/min | 35 ~55n/min | 35 ~55n/min | 35 ~55n/min | 35 ~55n/min |

| Steam Requirement | 250kg/h, 0.5~0.8Mpa | 300kg/h, 0.5~0.8Mpa | 400kg/h, 0.5~0.8Mpa | 500kg/h, 0.5~0.8Mpa | |

| Compressed air requirement | 0.2m³/min,0.4~0.6Mpa | 0.2m³/min,0.4~0.6Mpa | 0.25m³/min,0.4~0.6Mpa | 0.3m³/min,0.4~0.6Mpa | |

| Working Condition | /Temperature:20~25℃;n/Humidity:55% | ||||

| Total power | 6kw | 18Kw/380V | 27Kw/380V | 34Kw/380V | 38Kw/380V |

| Total Length | 1meter | 14m | 14m | 14m | 14m |

| Gross Weight | 300kg | 3500kg | 4000kg | 4500kg | 5000kg |

Write your message here and send it to us