Toffee candy making machine

Technical Specifications:

| Model | GDT150 | GDT300 | GDT450 | GDT600 |

| Capacity | 150kg/hr | 300kg/hr | 450kg/hr | 600kg/hr |

| Candy Weight | As per candy size | |||

| Depositing Speed | 45 ~55n/min | 45 ~55n/min | 45 ~55n/min | 45 ~55n/min |

| Working Condition |

Temperature:20~25℃;/Humidity:55% |

|||

| Total power | 18Kw/380V | 27Kw/380V | 34Kw/380V | 38Kw/380V |

| Total Length | 20m | 20m | 20m | 20m |

| Gross Weight | 3500kg | 4500kg | 5500kg | 6500kg |

Toffe candy making machine / caramel depositing line

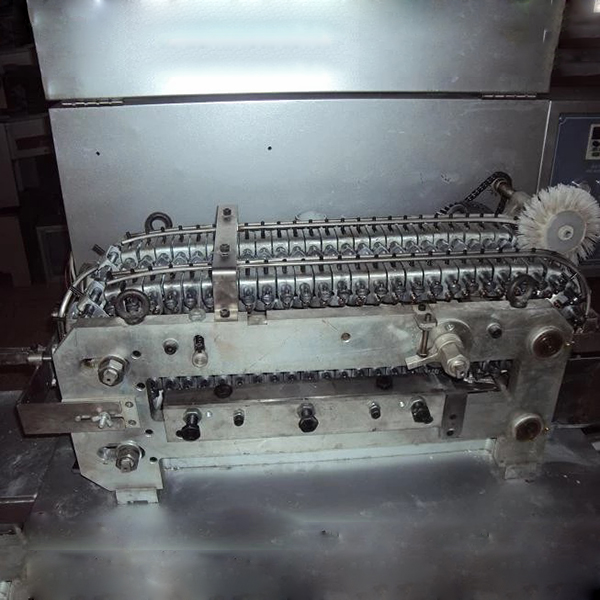

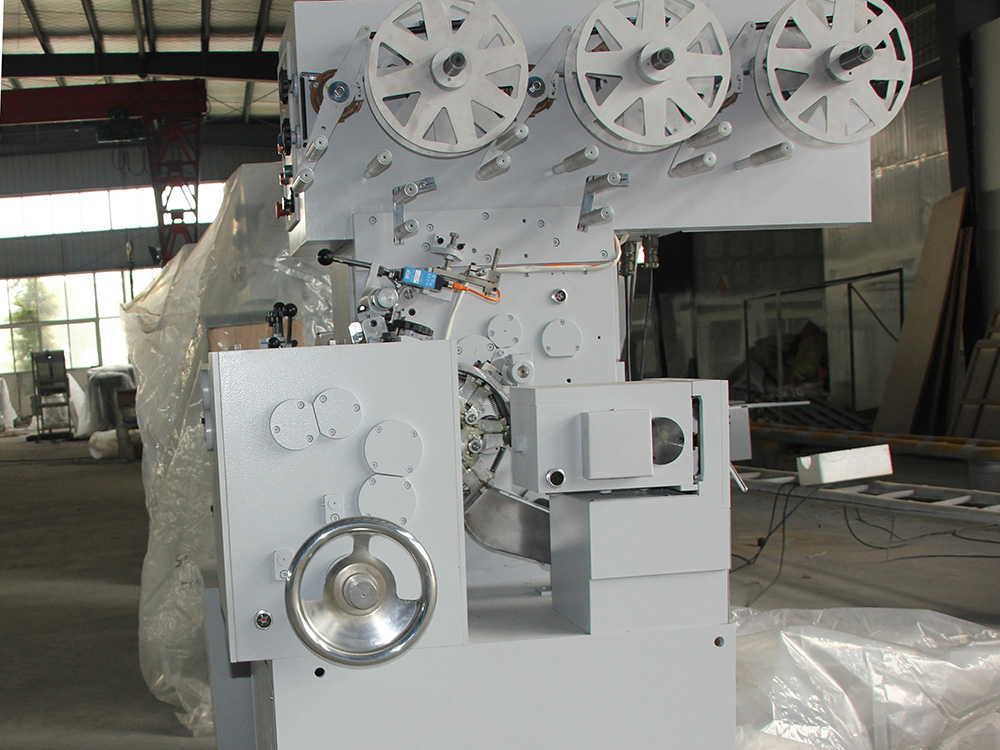

This die-molding former which consists of complete candy mass feeding system, set molding die, servo motor driving system, brushing system, controlling system, machine frame, candy conveying system is designed & updated for forming filled or without filled soft candy, milk candy, toffee candy, bubble gum candy after combining technologies from China and Europe.

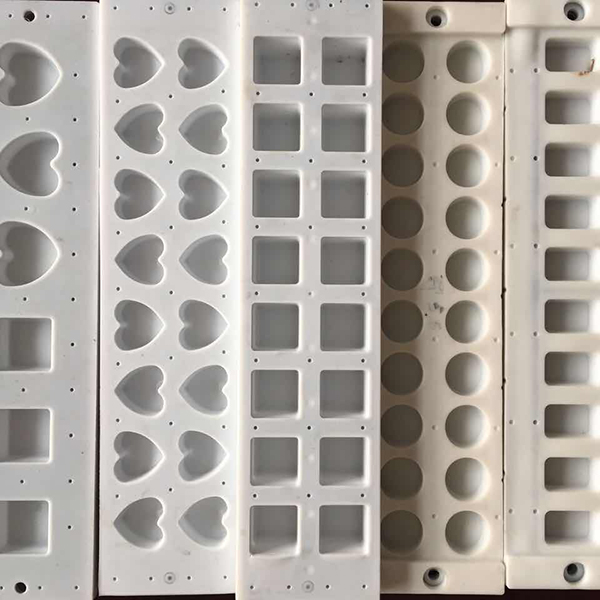

Forming different shapes of candies by chain molding die after getting the candy mass

| Name | Dimension (L*W*H)mm | Voltage(v) | Power (kw) |

Weight (kg) |

Output | |

| YC-200 | YC-400 | |||||

| Batch roller | 3400×700×1400 | 380 | 2 | 500 | 2T~5T/8h | 5T~10T/8h |

| Rope sizer | 1010×645×1200 | 380 | 0.75 | 300 | ||

| Lollipop Forming machine | 1115×900×1080 | 380 | 1.1 | 480 | ||

| 1685×960×1420 | 380 | 3 | 1300 | |||

| Cooling sifter | 3500×500×400 | 380 | 0.75 | 160 | ||

The equipments of toffee cutting production line and toffee die forming production line are basically the same, except for toffee forming part.The toffee cutting line is usually suitable for strip toffee or longer candy. It is cut and packaged according to the set size by entering candy cutting machine through candy rope sizing machine.