Gummy candy is a popular treat enjoyed by people of all ages. Known for their chewy texture and delightful flavors, gummy candies have become a staple in the confectionery industry. But have you ever wondered how these sweet treats are made? In this article, we will explore the fascinating process of gummy candy making, from start to finish. So let's dive in and satisfy our curiosity about this delectable treat! Learn more about Yucho's High Quality Gummy Candy Making Machine.

The first step in making gummy candy is to gather all the necessary ingredients. This includes gelatin, sugar, water, and flavoring agents. Gelatin is a protein derived from collagen, often sourced from animal bones and connective tissues. It serves as the main ingredient that gives gummy candy its characteristic chewiness.

Once the ingredients are ready, the gummy candy maker making process begins with heating a mixture of gelatin, water, and sugar. This mixture is heated to a specific temperature, usually around 240°F (115°C). Heating the mixture allows the gelatin to dissolve and blend with the other ingredients.

Next, the flavoring agents are added to the mixture. These can include natural or artificial flavors, such as fruit extracts or essences. The flavoring agents give gummy candies their distinct taste, ranging from fruity to sour flavors.

Once the flavors are added, the hot mixture is poured into molds. These molds can be in various shapes and sizes, depending on the desired gummy candy design. Traditional gummy candies are often shaped like bears, worms, or fruits, but modern gummy candy makers offer a wide range of unique shapes and designs.

After pouring the mixture into the molds, it is essential to allow the candy to cool and set. This usually takes a few hours, depending on the size and thickness of the gummy candies. Cooling allows the gelatin to solidify and gives the candies their chewy texture.

Once the gummy candies have hardened, they are removed from the molds. At this stage, the candies may still be slightly sticky, so a powdered coating is often applied. This coating, typically made of cornstarch or a similar substance, helps to prevent sticking and makes the candies easier to handle.

Now that the gummy candies are ready, they undergo a final inspection for quality control. Any misshapen or damaged candies are discarded, ensuring that only the best candies make it to the market.

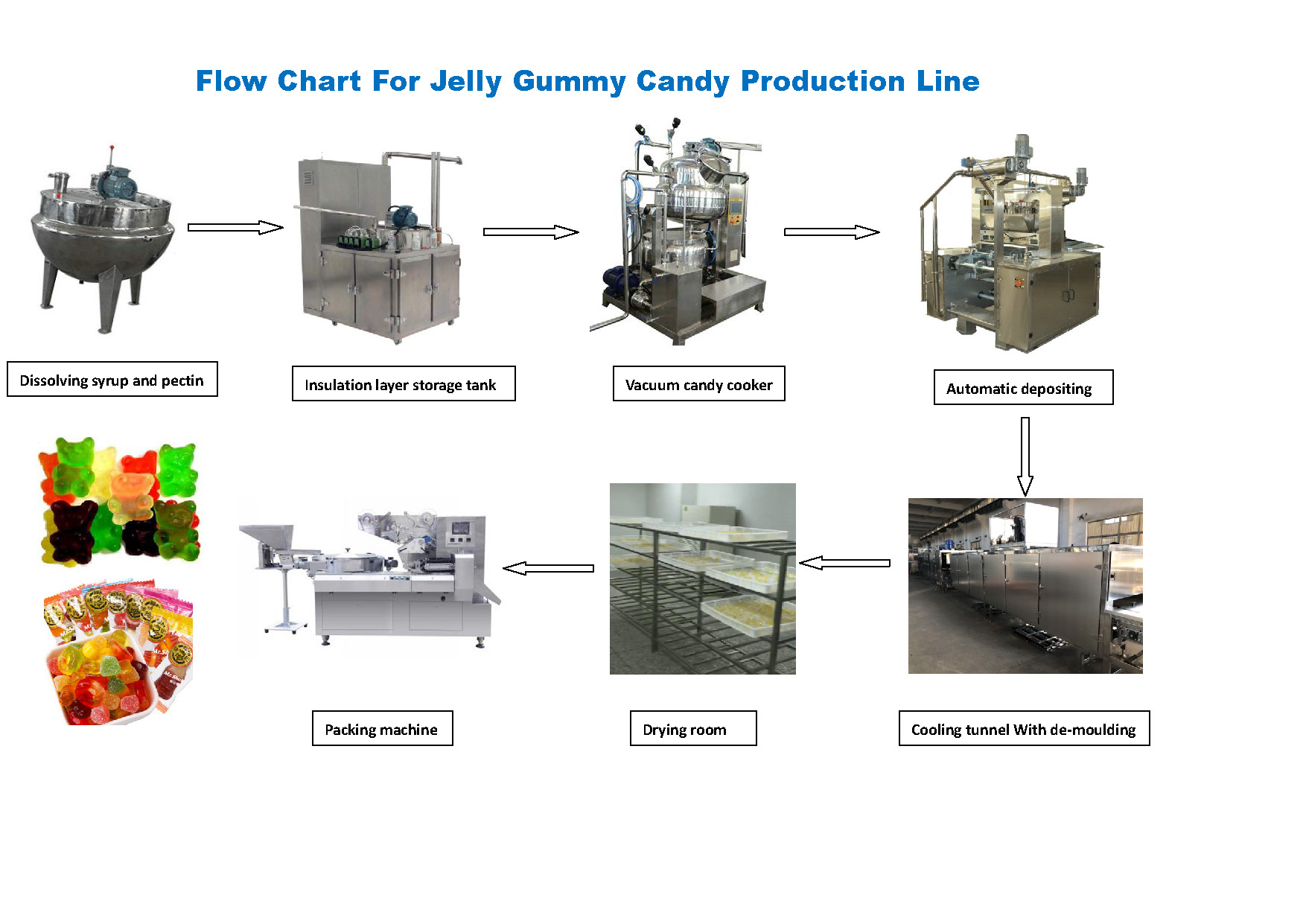

In recent years, advancements in technology have led to the introduction of gummy candy-making machines. These machines allow for a more efficient and consistent production process. Gummy candy makers can now automate the pouring, cooling, and shaping processes, reducing human labor and enhancing overall productivity.

Additionally, gummy candy makers have started to experiment with unique flavors, textures, and even nutritional compositions. Some manufacturers are creating gummy candies with added vitamins, minerals, or functional ingredients like CBD. These innovations are driven by the increasing demand for healthier and more diverse gummy candy options.

In conclusion, the process of making gummy candy involves a careful combination of ingredients, heating, flavoring, molding, cooling, and quality control. From the traditional gummy bear to modern and innovative designs, gummy candy has come a long way. So the next time you indulge in this tasty treat, take a moment to appreciate the craftsmanship and dedication that goes into making your favorite gummy candies.

Post time: Jul-26-2023