If you have ever visited a candy shop or attended a fair, you have likely come across the delightful treat known as taffy. This soft and chewy candy has been enjoyed by people of all ages for decades. But have you ever wondered how taffy is made? The answer lies in a fascinating piece of machinery called a taffy machine. In this article, we will explore what a taffy machine is, its components, and how it works to create the delectable taffy candy.

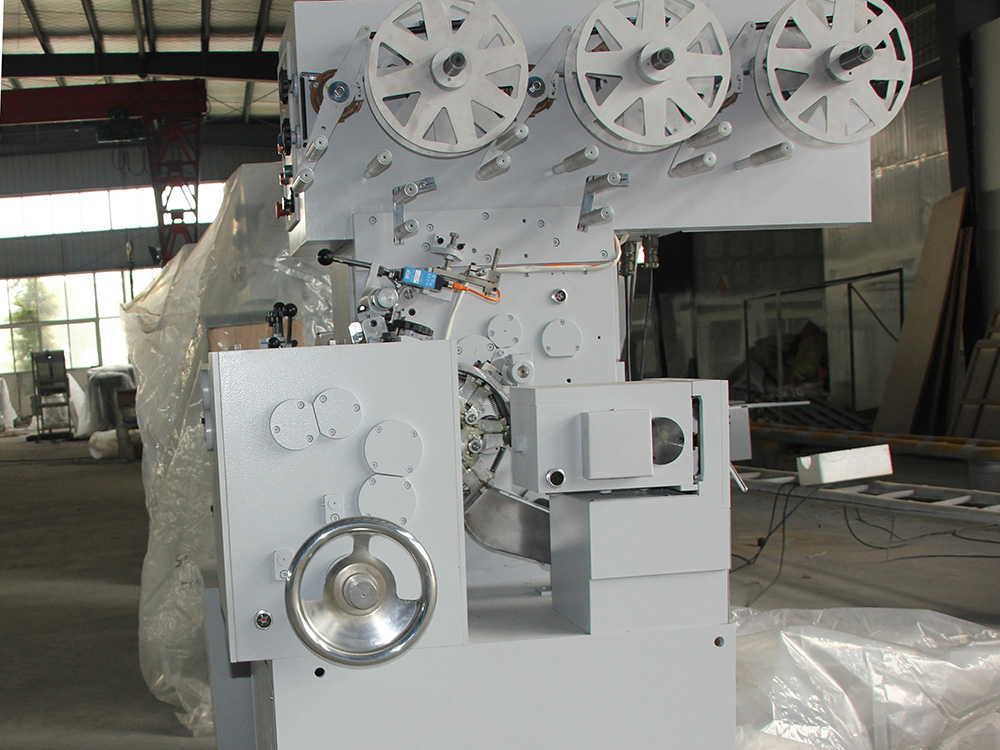

A taffy machine, also known as a taffy puller, is a specialized piece of equipment used in the candy-making industry. Its primary function is to stretch and pull the taffy mixture to give it its distinctive texture. Let's take a closer look at the components of a taffy machine and how they work together to create this tasty treat.

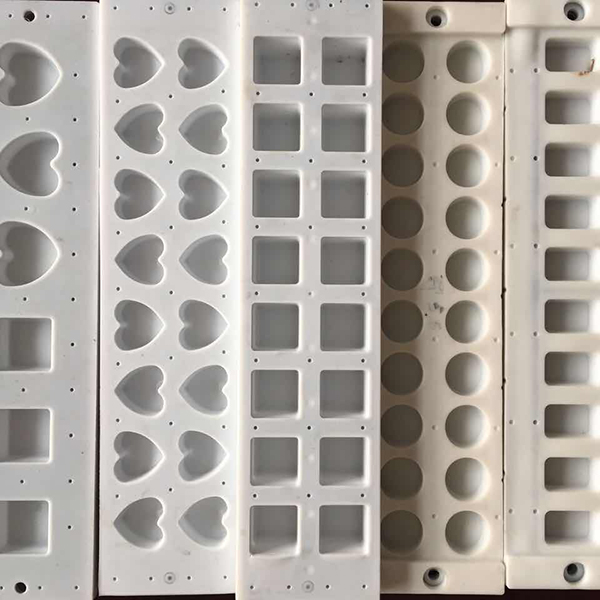

Depositing Machine

1. Bowl or Kettle:

The taffy-making process begins with a large metal bowl or kettle. This is where all the ingredients are combined to create the taffy mixture. The bowl is heated, and the ingredients are melted together until they form a smooth and sticky syrup.

2. Beaters or Paddles:

Once the taffy mixture has been prepared in the bowl, it is time to transfer it to the taffy machine. The machine consists of two large rotating beaters or paddles. These beaters are responsible for continuously mixing and aerating the taffy mixture as it passes through the machine. This helps to incorporate air into the mixture, making it light and fluffy.

3. Cooling Chamber:

As the taffy mixture moves through the machine, it enters a cooling chamber. This chamber is typically refrigerated or chilled to cool down the warm taffy mixture. The cooling process helps to stabilize the candy and prevents it from becoming too sticky during the stretching and pulling phase.

4. Stretching Mechanism:

After the taffy mixture has been cooled, it enters the stretching mechanism of the machine. This is where the real magic happens. The stretching mechanism consists of several pairs of mechanical arms or rollers that pull and stretch the taffy. These arms slowly and rhythmically stretch the taffy, causing it to become thinner and longer. This stretching action also aligns the sugar molecules within the taffy, giving it its characteristic chewy texture.

5. Flavoring and Coloring:

While the taffy is being stretched and pulled, flavorings and colorings can be added to the mixture. These ingredients are carefully incorporated into the taffy to create a wide range of flavors and colors. Some common flavors of taffy include vanilla, chocolate, strawberry, and peppermint. The colors can vary from traditional shades like pink and yellow to more vibrant options like blue and green.

6. Cutting and Packaging:

Once the taffy has reached the desired consistency and has been flavored and colored, it is ready to be cut and packaged. The stretched taffy is typically fed into a cutting machine, which slices it into bite-sized pieces. These individual pieces are then wrapped in wax paper or plastic wrappers and prepared for sale or distribution.

So, now that we understand the various components and processes involved in a taffy machine let's take a closer look at how it works in action.

1. Preparation:

Before starting the taffy-making process, all the ingredients, including sugar, corn syrup, water, and flavorings, are measured and combined in the bowl or kettle. The mixture is then heated and melted until it reaches the desired temperature and consistency.

2. Mixing and Aeration:

Once the taffy mixture has been prepared, it is transferred to the taffy machine. The rotating beaters or paddles in the machine start mixing and aerating the taffy. This continuous mixing process helps to incorporate air into the mixture, giving the taffy its light and fluffy texture.

3. Cooling:

After the taffy mixture has been mixed and aerated, it enters the cooling chamber. The chamber is chilled to cool down the warm taffy, stabilizing it and preventing it from becoming too sticky during the stretching and pulling phase.

4. Stretching and Pulling:

As the cooled taffy enters the stretching mechanism, the mechanical arms or rollers slowly and rhythmically stretch it. This elongation process aligns the sugar molecules within the taffy, giving it its characteristic chewy texture. The taffy becomes thinner and longer as it moves through the machine.

5. Flavoring and Coloring Addition:

While the taffy is being stretched and pulled, flavorings and colorings can be added to the mixture. These ingredients are introduced at the appropriate stage of the process and mixed thoroughly into the taffy. The flavors and colors are carefully chosen to create a wide variety of taffy options.

6. Cutting and Packaging:

Once the taffy has undergone the stretching and flavoring process, it is ready to be cut and packaged. The stretched taffy is fed into a cutting machine, which slices it into individual pieces. These pieces are then wrapped in wax paper or plastic wrappers and prepared for sale or distribution to candy shops, fairs, or other venues.

In conclusion, a taffy machine is a fascinating piece of machinery that transforms a simple mixture of sugar, flavorings, and colorings into the delightful treat we know as taffy. It combines various processes like mixing, stretching, flavoring, and cutting to create the soft and chewy candy loved by many. The next time you enjoy a piece of taffy, you can appreciate the intricacies involved in its creation thanks to the incredible taffy machine.

Post time: Aug-14-2023