Gummies have become a popular treat among people of all ages. Their chewy texture and delightful flavor make them a favorite choice for many candy lovers. But have you ever wondered how these colorful and fun-shaped candies are made? Behind every gummy candy lies a carefully crafted process that involves various machines and techniques. In this article, we will explore the world of gummy candy making and shed light on the machines used in the process.

One of the primary machines used in gummy candy production is the gummy candy maker. This machine is specifically designed to mix, heat, and cool the ingredients required for making gummies. The gummy candy maker typically consists of a large, stainless steel tank with a heating and cooling system, an agitator, and a depositor.

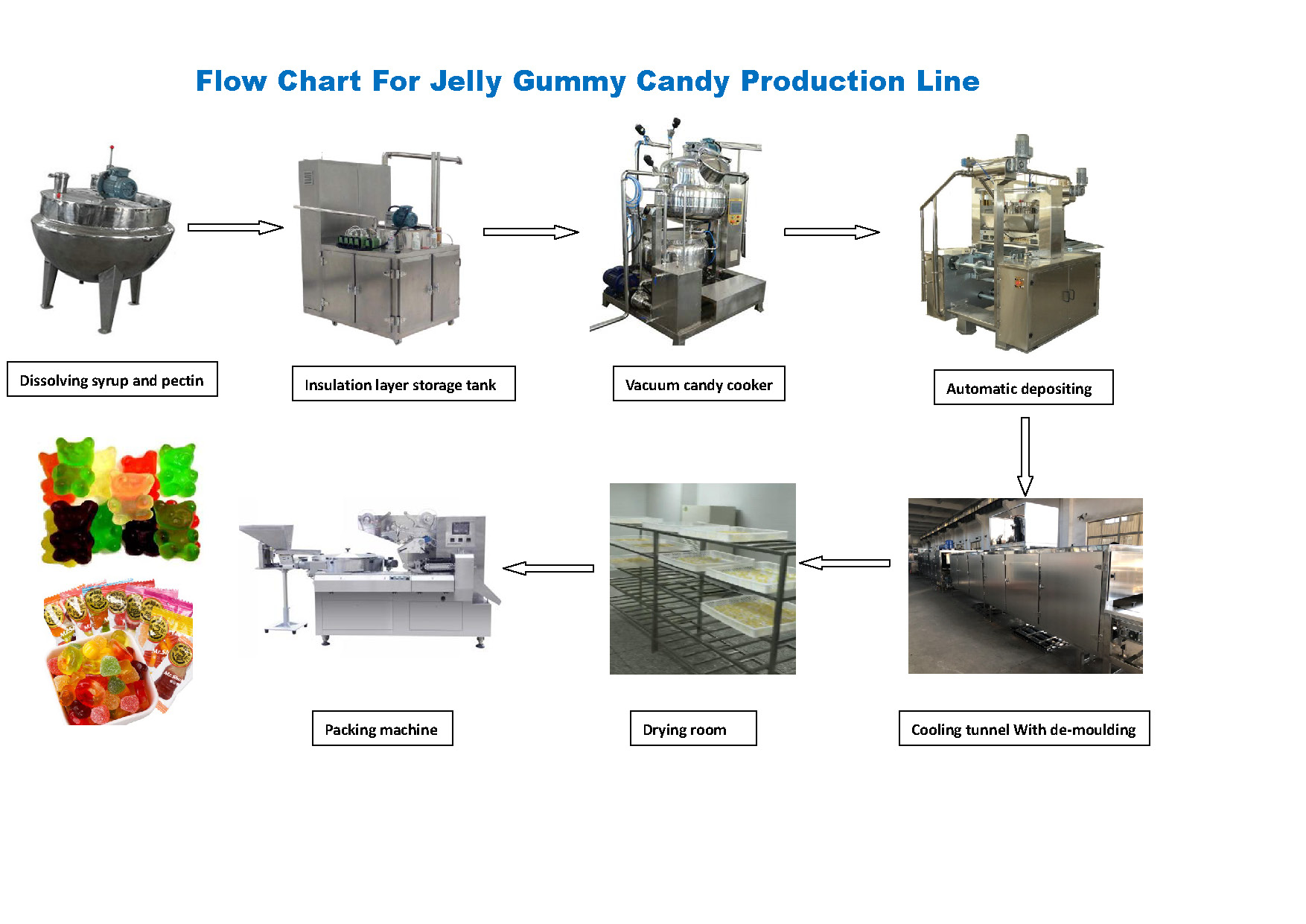

The first step in the gummy candy making process is mixing the ingredients. The machine's agitator blends the ingredients, including gelatin, corn syrup, sugar, flavorings, and food coloring, to form a smooth and consistent mixture. The agitator is designed to ensure that all the ingredients are evenly distributed, preventing lumps or clumps from forming. The machine's capacity determines the quantity of gummy candy that can be produced in one batch.

Once the ingredients are thoroughly mixed, the mixture is heated to dissolve the gelatin and activate its gelling properties. The heating system of the gummy candy maker allows precise temperature control to ensure the gelatin reaches its optimum melting point. This step is crucial as it determines the texture and elasticity of the final gummies.

After the mixture has been heated, it is cooled down using the machine's cooling system. This step is essential to solidify the gummy candy mass and give it the desired chewy texture. The cooling process also helps to prevent the gummies from sticking together or becoming too soft.

Once the mixture has cooled, it is ready to be shaped into various gummy candy forms. This is where the depositor comes into play. The depositor is a machine component that dispenses the gummy candy mixture into the desired molds or trays. It ensures that each mold is filled evenly and accurately, creating consistent shapes and sizes for the gummies. The depositor's precision and efficiency contribute to the overall quality of the gummy candies produced.

In addition to the gummy candy maker and the depositor, other machines are used in the gummy candy making process to enhance productivity and efficiency. For instance, a cutting and embossing machine is employed to cut the gummy candies into individual pieces and give them their unique shape and design. This machine can produce a wide variety of gummy shapes, from animals and fruits to letters and numbers.

Another important machine used in the gummy candy manufacturing process is the drying tunnel. After the candies are shaped, they need to undergo a drying process to remove excess moisture and further enhance their texture. The drying tunnel provides a controlled environment with controlled temperature and humidity, allowing the gummies to dry without losing their chewiness.

Moreover, gummy candy manufacturers often use a packaging machine to package the finished gummy candies. These machines can automatically weigh, seal, and label the gummy candy bags or boxes, streamlining the packaging process and ensuring hygiene and accuracy.

In conclusion, the production of gummy candies involves a series of steps and machines. The gummy candy maker with its mixing, heating, and cooling capabilities forms the core of the process. The depositor, cutting and embossing machine, drying tunnel, and packaging machine further contribute to the creation of high-quality, delicious gummy candies. Understanding the machines used in gummy candy production gives us a deeper appreciation for the time and effort invested in creating these beloved treats. Next time you enjoy a gummy candy, remember the intricate journey it went through before reaching your taste buds.

Post time: Jul-28-2023